“

With more than 20 years' experience in the raised access floor industry, we are a professional overall raised access floor supplier with global influence.

”

Over the years, Resflor has connected an expansive clientele, including different major land developments, government entities, private sectors, architects, contractors and facilities managers. In addition, we also have a team of engineers and specialized personnel offering their expertise to the construction market.

Our success is based on the provision of a wide product selection, premium quality, professional and expert consultancy service, and detailed craftsmanship after-sales services. More than 20 years of R&D&I, design, manufacturing has become our customer’s reliable source.

Milestones

2024

2023

2022

2021

2020

2019

2018

2016

2015

2014

2013

2010

2008

2003

1996

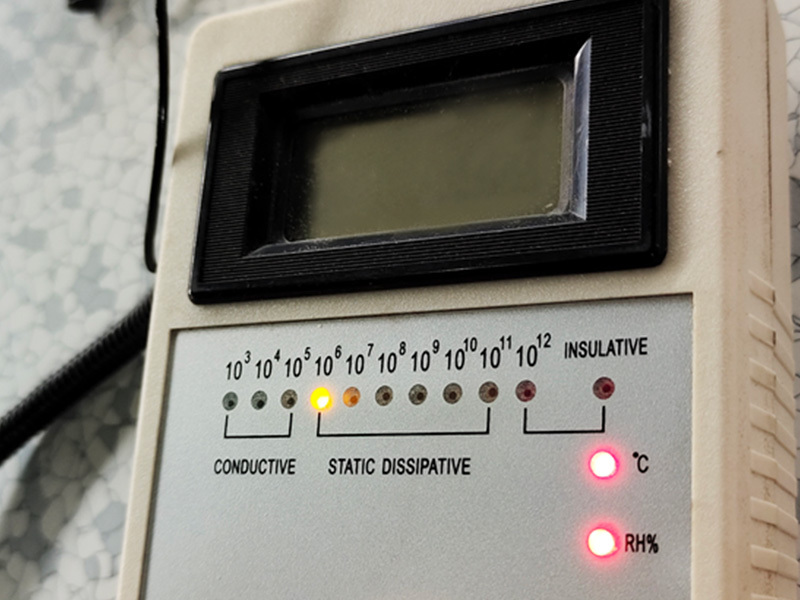

How Resflor QC Works

At Resflor, we have over 20 years of professional experience in manufacturing raised access floor. We ensure that every process is done to the highest possible standards for our client's satisfaction.

Pre-inspection Before Production

We always launch a successful product that meets all customers’ needs and expectations. We must ensure that everything is ready and working well before starting the production process. Pre-production inspection is so important because it helps you check and fix any issues that might affect the quality of your product.

In process Inspection

The key product quality control points and section chief responsibility system were designed in each production process. The staff are required to report the daily core-data on product quality to QC management on time.

Randoms Inspection

In addition to in-process inspections, our QC team will randomly check key quality control points in different production processes to ensure that there will be no product quality problems that will affect other related processes.

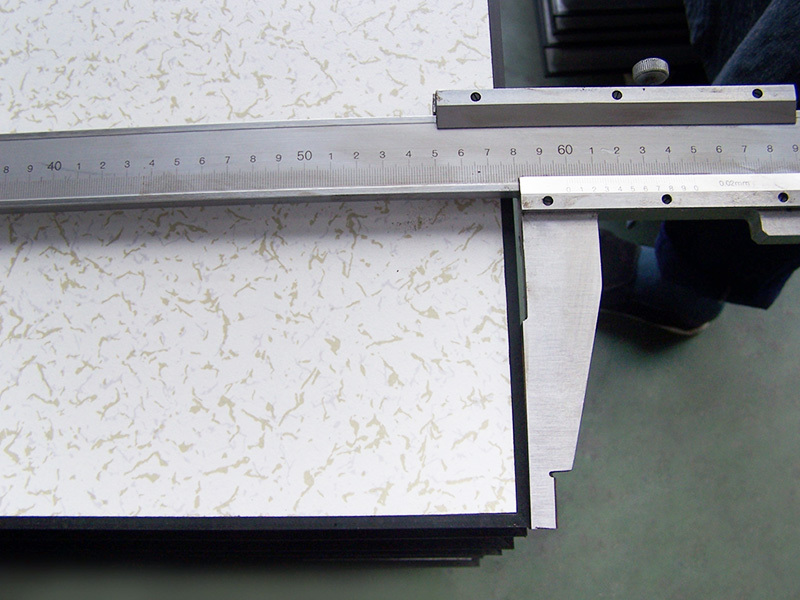

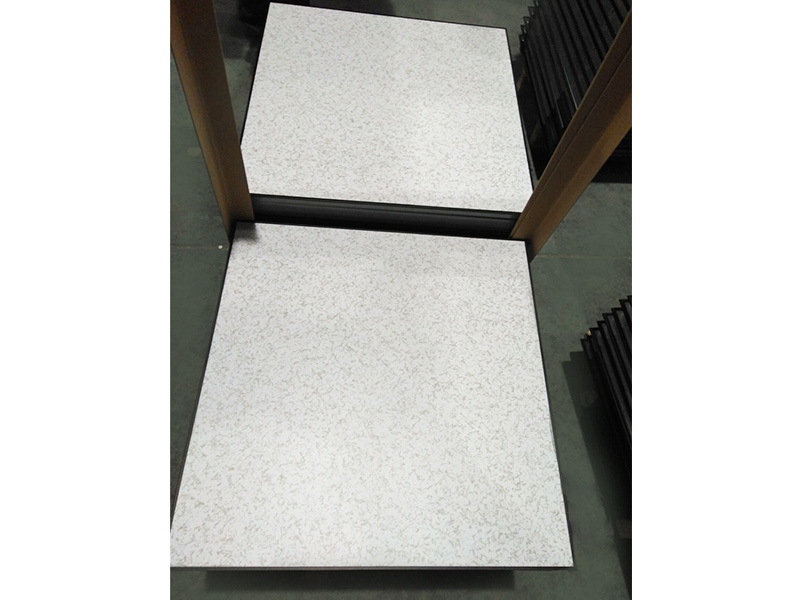

Piece Inspection Before Packing

To keep 100% qualified product rate, piece inspection is required in packaging process when the finished floor panel is packed. Any defective product is not allowed to deliver to customers. We also have built the quality traceability system to trace the defective products to certain process in order to improve it for the next time.

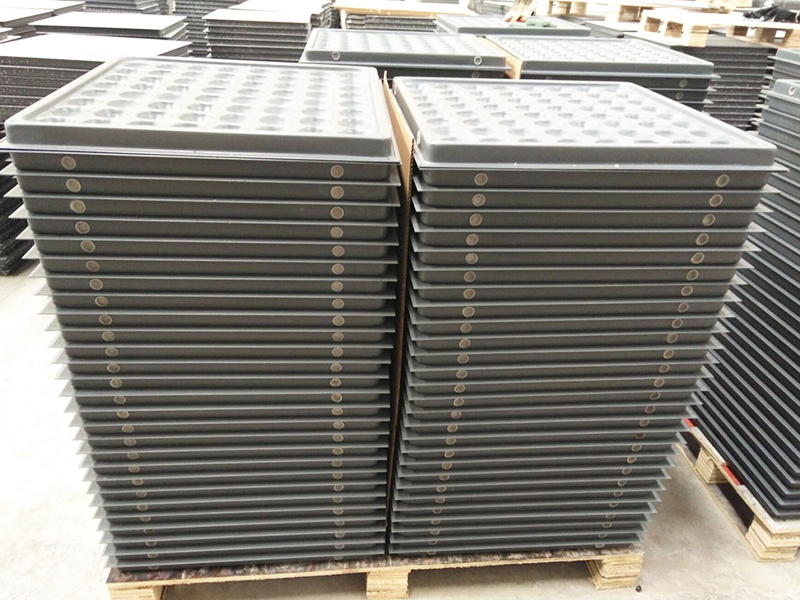

Final Inspection Before Shipment

Following the work process of a professional inspection company, we will conduct random inspections according to a certain percentage of packages, and issue a final inspection report after each batch of product packaging is completed.

After-sale Service Never End…

The customer service never ends. We will take responsibility for our customers after sales in our quality warranty period. If you have any queries regarding product quality, installation and maintenance, or customer service issues, or need any technical support from us, you can contact our service team at any time.

R&D&I

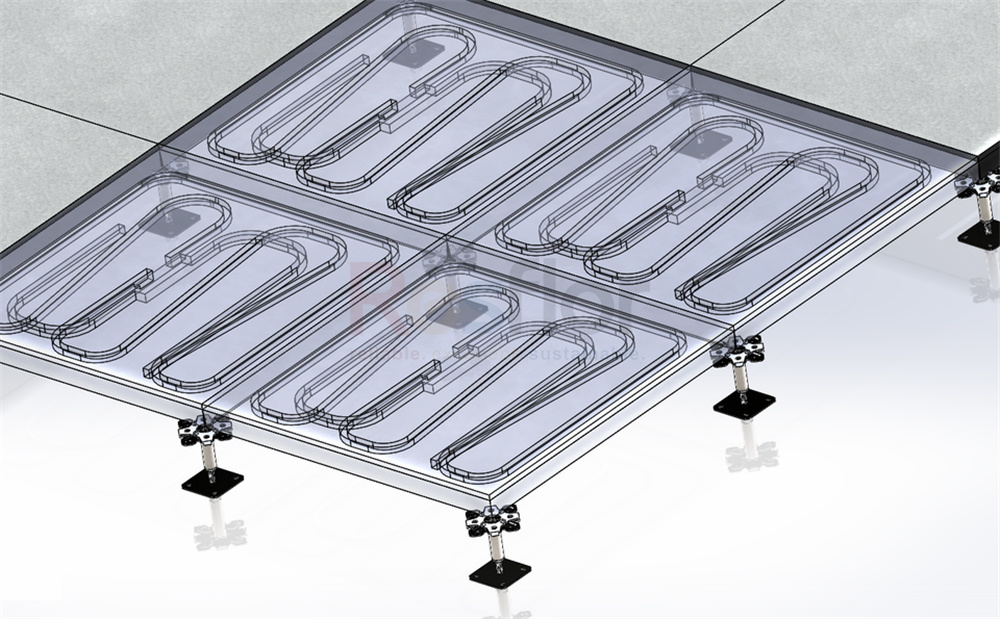

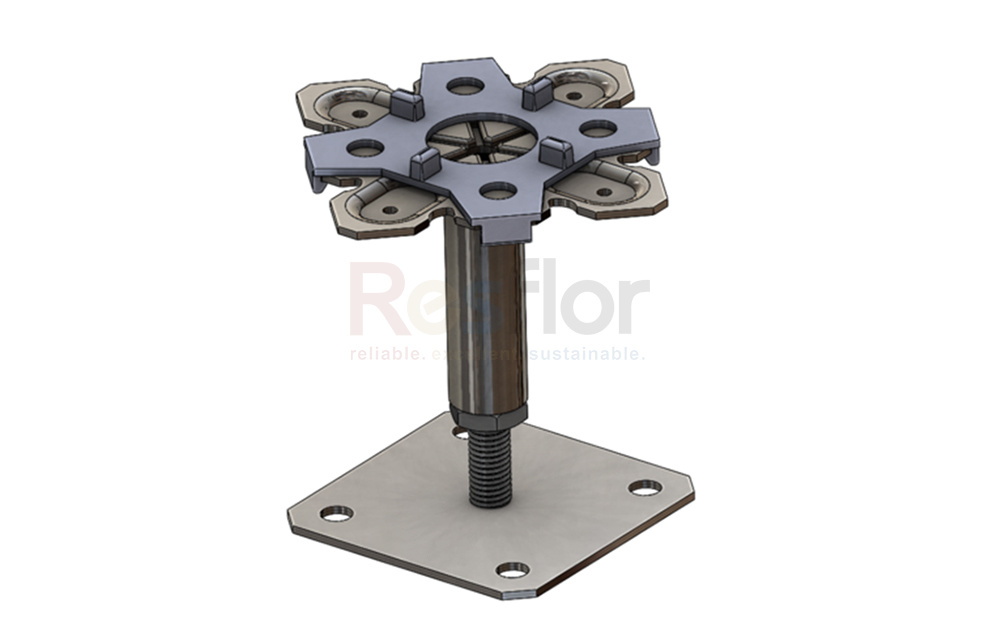

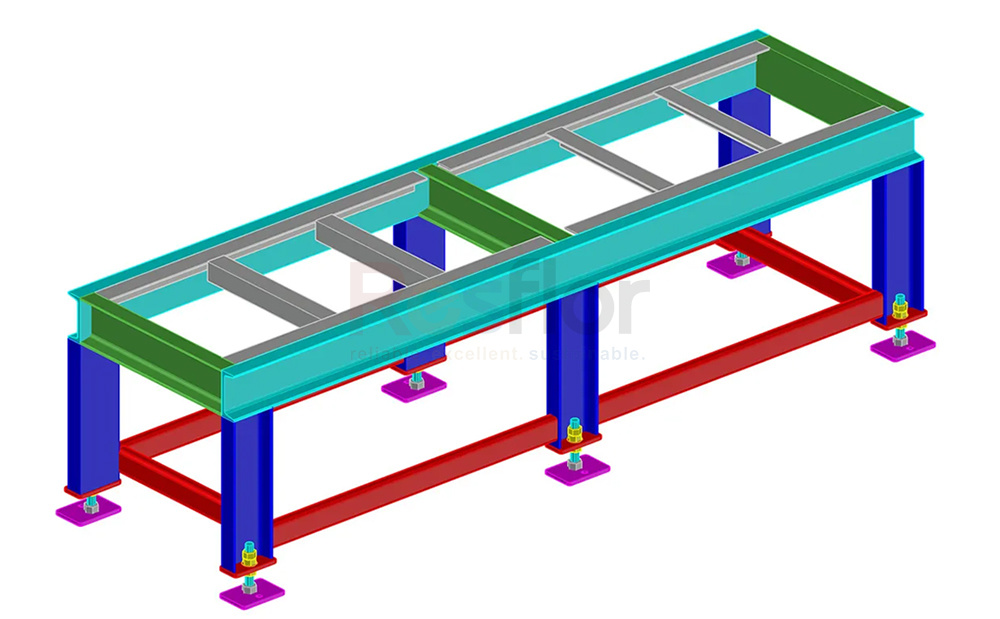

With more than 20 years of manufacturing experience in the raised access floor industry, and with a full set of supply chain support from raw materials to final products, Resflor Floor provides full sets of ODM/OEM services. Whether you have your own design or the special specification requirement, or you partner with us for the pre-designed flooring products, Resflor is your reliable partner from the design to the final production, to guarantee the desired results.

RESEARCH & DEVELOPMENT & INNOVATION

Our engineers with excellent professional skills, experience, reliability, creativity, flexibility are responsible for upgrading the existing products/solutions, and innovating the new ones. With the rapid development of global economy and industry, Resflor must continually upgrade our design and range of products/solutions. It’s crucial for acquiring larger market share and for company survival.

Customization and Flexibility

One of the significant advantages of Resflor raised floor is our ability to customize according to the specific needs, whether it's unique panel sizes, surface finishes, or integrated components, etc.

Our engineering team provides support with tools like AutoCAD, SolidWorks, Autodesk Revit, Adobe Photoshop, and Adobe Illustrator. We can provide complete sets of CAD drawings (in AutoCAD and SolidWorks formats) for the whole series of flooring systems, related products, and every component.

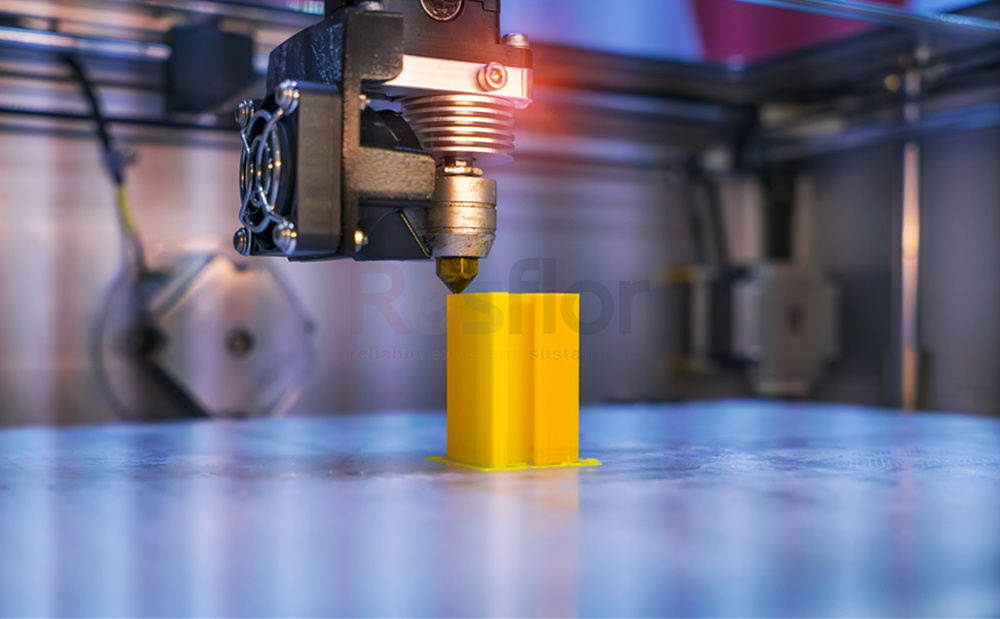

Smart Manufacturing

We have advanced equipment and machines such as 3D printers, laser cutters, imported shearing and folding machines, which are equipped with cutting-edge technology. These are used to help clients solve specific problems such as complicated installation conditions. This means that we could customize everything you need to assist, help and even support clients in sales, installation and service of the raised access floor system.

Contact Us

Brand Head office: Building 8, Swan Lake Garden, Tianning District, Changzhou City, Jiangsu, China. 213004

Factory: Hengshanqiao, Wujin District, Changzhou City, Jiangsu, China. 213119

Tel: +86-519-88103880

Fax: +86-519 88103880

Copyright © 2024 SC NEW MATERIAL INC